- Home

- Centrifugal Pumps

- Horizontal Centrifugal Pump

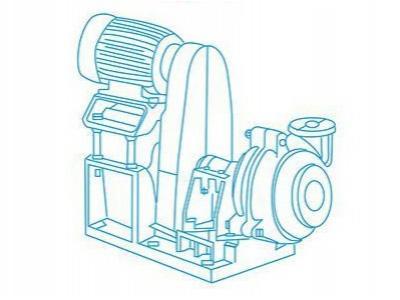

Horizontal Centrifugal Pump

Our horizontal centrifugal pump has a simple structure, stable operating and easy maintenance. The pump is applicable for handling liquids with high concentration of ore, mortar, cement and other suspended solid particles. Such fluids are typically highly abrasive and/or corrosive. Thus, in designing the horizontal centrifugal pumps, we have thoroughly considered these features:

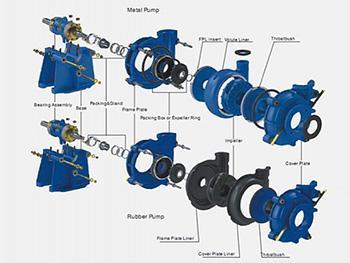

1. Pump casing

Horizontal centrifugal series pumps typically feature a double-casing design. That is, other than the whole external pump casing, there is also a detachable casing inside the pump. After operating for a while, the internal pump casing is worn out and can be changed directly without replacing the whole pump. The cost is greatly reduced.

2. Wet end

This series horizontal centrifugal pump is mainly used for conveying highly abrasive mediums. Therefore, wear-resistant high chromium alloy is adopted to manufacture the wet ends, including the impeller, liner and so on. The material for the liner of the centrifugal pump is available in metal and rubber to pump different mediums. And the two liners are interchangeable to obtain flexible assembly.

3. Motor

Horizontal centrifugal pump adopt a stable horizontal structure. Its maximum motor power can reach 1200kW, making it better applicable to various complex working conditions.

To satisfy different demands, Zidong can not only supply the common specifications of pump, but also produce custom pumps following your requirements.

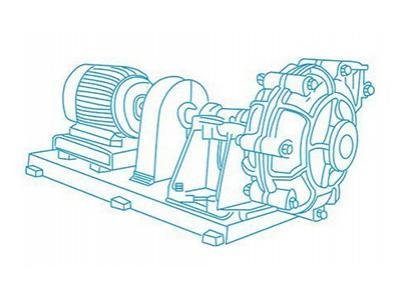

DC Drive

DC drive reduces the transmission energy loss between pump and the motor. Offering high efficiency, it is used under the same speed of the motor and pump.

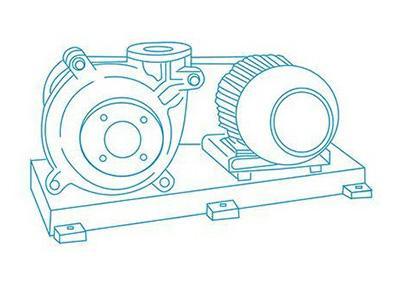

CR/CL drive

The motor can be installed on the left or right side of the pump.

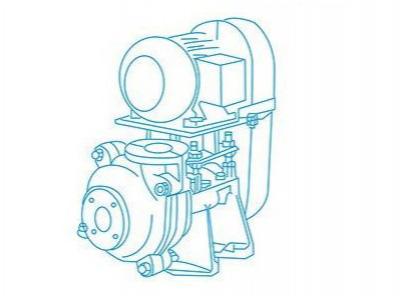

CV Drive

CV belt drive. The motor is fixed above the bracket connected with the pump shaft, saving foot print.

ZVZ Drive

ZVZ belt drive, the motor is fastened on the frame at the end of the pump and the belt is between the pump and motor.